Anti-Static Plastic Sheets in the Chemical Industry: Protecting your Products and Processes

Can you ask yourself a question what is the way the products are protected and by which means during the manufacturing process? When and how chemicals are transported in and out of this country and still not affecting the environment in a negative way? Here, an example from chemical industry can be useful. The answer is as follows: using of anti-static plastic sheets.

What Are Anti-Static Plastic Sheets?

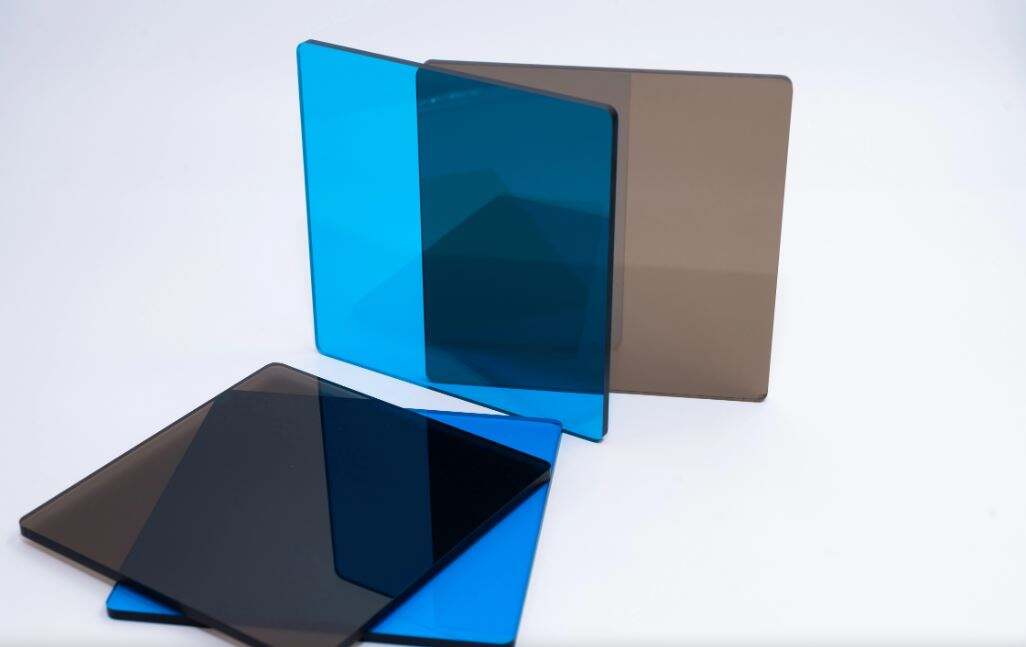

Anti-static plastic sheets are those type of sheets that are made of a special polymer, which minimizes the possibilities of static electricity charges. Due to this they are suitable for applications where static electricity is detrimental, for instance in the chemical industry.

Advantages of Anti-Static Plastic Sheets

For a long time, anti-static plastic sheets by Andisco have been relevant in the chemical industry in the following ways. They are:

1. Innovation: The placement of anti-static plastic sheets is one of the brilliant measures that have been employed to avoid the risks of static electricity.

2. Safety: Using of Anti-static plastic sheets also provides protection to the products and the processes because of the static electricity which these most times cause such hazards like explosions and fires.

3. Use: It can be used as a protective layer of the raw materials, semi-finished products or the final product or can act as an outer covering for materials used for transportation and storage.

4. How to Use: Some of the benefits that can be caught with ESD Anti Static sheets are that they are relatively easy to use. Basically, all you need to do is to put them right over the material of your choice and ensure that it is clean and dry.

5. Service: They similarly serve a service protection function by slowing the degradation of highly sensitive chemicals and materials through the application of anti-static plastic sheet.

Quality and Application

In relation to the chemical industry the quality of anti-static plastic sheets is important for the protection of the products. Ideally, they ought to be evaluated and certified to adhere to the necessary standards in a way that they lower down chance of static electricity in the production process.

The uses of anti-static plastic sheets in the chemical industry can be counter intuitive but they are numerous. They are used to:

1. Tie down polymer used in covering raw materials for minimizing static build-up during storage.

2. Minimize exposure and risk to important papers or documents by ensuring that they are secure during transport.

3. To prevent the accumulation of static electricity during preparation and handling of chemical mixtures.

4. The packaging of the product should do this prevent the finished products from being affected by static electricity.

5. Reduce the cases of chemical reactions and thereby increase the shelf-life of the chemicals by minimizing the buildup of static electricity.

Anti-static plastic coverings are also used in various establishments other than industries like in laboratories where specific equipment cannot be exposed to static electricity.

Conclusion

Therefore, it is important that those involved in the chemical production value chain have a working knowledge on the proper use of antistatic plastic sheets. These sheets have given an advanced approach to eliminate the static electricity hazards while consisting of extra advantages like Service protection, Shelf-life and ease in use.

In selecting anti-static Plastic Sheet, it is necessary to make sure that they are of the best quality as to effectively serve the purpose required for them. This way, you secure your processes and products are safe and at the same time act responsibly towards the environment and future generations in the area of manufacturing processes.