Anti-Static Acrylic Sheets: Keeping Electronics Safe

Being an essential product category in our daily usage, electronics have become an indispensable part of most households. They help in talking through smart phones, helps in entertainment through gaming computers, and also helps in working through office computers. However, I would like you to learn the fact that some risks are present in the manufacturing process of these devices. I had one of them, namely the static dangerous electricity to component parts. Fortunately, there is a solution: anti-static acrylic sheets.

Advantages of Anti-Static Acrylic Sheets

To begin with, it is necessary to define what anti-static garment exactly implies. Static electricity refers to a form of electricity that can be found on objects, structures or any given surface. Whenever there is rubbing of two surfaces, one acquires a higher static charge compared to the other one and hence when they come in contact, they can cause sparks due to the transfer of electrons. In electronics manufacturing, the completion of this can negatively affect delicate components such as the circuit boards or chips. Ordinary anti-static material is much like any other material but possess a surface charge that disperse the static electricity so as to avoid causing harm.

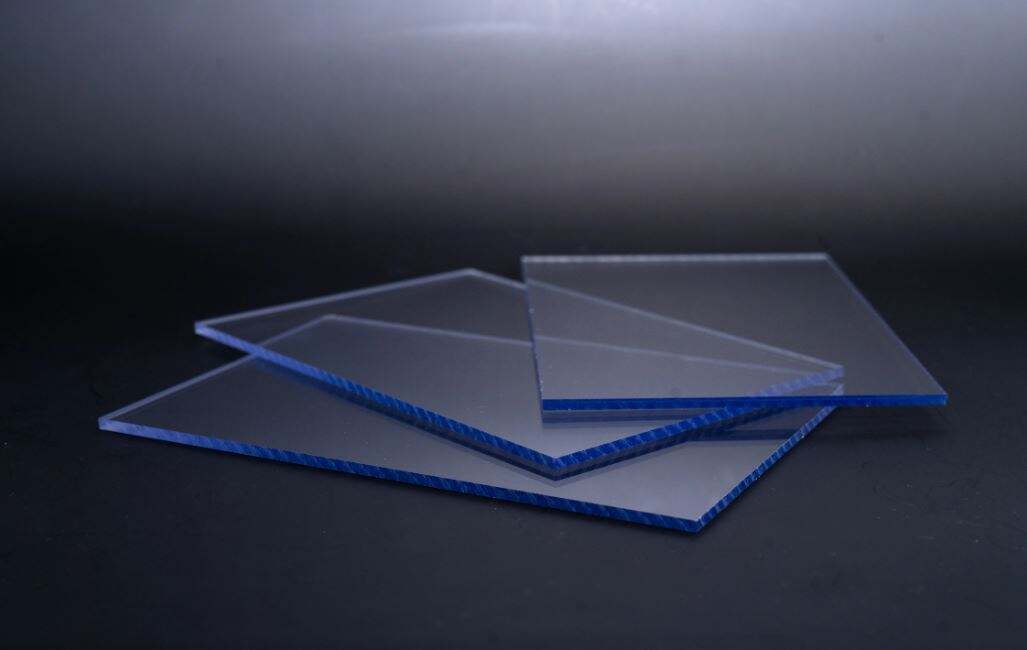

Manufacturers prefer acrylic sheets because of their lightweight, robustness and the ability to bend them into various forms. When combined with anti-static, they are perfect for electronics market in addition to their thermal conductivity, they possess qualities such as the existence of anti-static properties. Anti-static acrylic sheets have the following advantages: Anti-static Acrylic Sheet by Andisco have the following advantages:

- They eliminate the chance of static build up in manufacturing environment so that the sensitive parts of the electronics products do not get damaged.

- They are clear and this helps in ensuring that one can have an easy check on the products being produced.

- They are also more resilient to impacts and crushing forces as well as conform to safety standards in handling workers.

- They are easy to clean and take minimal effort in maintaining hence making them have long service times.

Innovation in Manufacturing Safety

Using anti-static acrylic sheet is just one of the creational ways that enhances on the security of production as a principle. This paper argues that anticipated hazards and products for specific areas help companies and manufacturers in shielding their workers and products. Hence in electronics manufacturing, the costs resulting from the damages caused by static are not only the delays that the manufacturing process experiences but also the loss of customer trust resulting from the damaged products. Through practicing the use of ESD Anti Static materials, one can effectively minimize such risks while upholding quality production.

How to Use Anti-Static Acrylic Sheets

Handling and applying anti-static acrylic sheets are quite a simple process. They can be in the form of cutting and molding, and fabrication for the proper needs of a given material kind. When dispensing them, one should use gloves because touching the coating could cause a loss of its characteristics. It is recommended that when using paper products such as the sheet, an anti-static wrist strap or grounding mat may be worn to discharge any static that could have been accumulated. It is also desirable to keep the sheets in a dry and rather low temperature to avoid the deterioration of the anti-static coatings.

Service and Quality

Selecting the most suitable supplier of anti-static acrylic sheets is a wise decision to make because it determines quality. A supplier of CCTV systems should have experience in the electronic business and sales; personnel from the supplier should be able to offer technical support in things like the choice of the best product to purchase and installation. They should also bring forth options that will help the client to meet the exact requirements as needed. Siliconized material also has to be checked for quality control because any seams where the silicon has not adhered well will compromise the anti-static properties of the material.

Application in Electronics Manufacturing

Used in the manufacturing processes of electronics, anti-static acrylic sheets are a common product that can be incorporated in the production of any given stage. They can also be employed as shields for protecting the circuit boards, chips among other related component during the assembling and testing phases. They can also be used in the form of work-tables, anti-static flooring or mats, or shelves for the storage of material to avoid accumulation of static electricity charges. Furthermore, they can be applied in anti-static Plastic Acrylic Sheet for cleanroom system to ensure that systematic environment is not contaminated.

Conclusion

Anti-static acrylic sheets are something that is actually important in the safety aspects of manufacturing electronics. They minimize the threat of static electricity affecting the functionality of the constituents of the products, thus maintaining a good quality standard. They are very simple to utilize and manage, and one can often get assistance from a reliable supplier and quality material. This paper notes that by embedding anti-static materials into their processes electronics manufacturers can safeguard their products and employees.