In today's technology-driven world, the demand for specialized materials that ensure safety, precision, and durability continues to grow. Among these, anti-static plastic sheets (also known as ESD plastics) have emerged as critical components in industries ranging from electronics to aerospace. Their unique capacity to dissipate static charges, protect sensitive equipment, and maintain operational integrity makes them indispensable. Let's explore their cutting edge applications across sectors.

1. Precision Instrument Protection

Anti-static plastic sheets are vital for safeguard high-precision instruments in laboratories, research facilities, and manufacturing units. These sheets prevent electrostatic discharge (ESD) that could damage delicate components such as micro sensors, optical devices, otherwise calibration tools. By integrating static dissipative coating layers into instrument housings or workstations, manufacturers ensure long-term reliability and accuracy in environments where even minor static interference is unacceptable.

2. Packaging Industry Innovations

In packaging, anti-static plastic films and trays are revolutionizing the transport of electronics, circuit boards, and sensitive medical devices. These materials neutralize static buildup during handling and shipping, preventing dust attraction or component degradation. Customizable designs, such as conductive foam inserts or thermoformed ESD containers, offer tailored protection for fragile items while complying with international shipping standards.

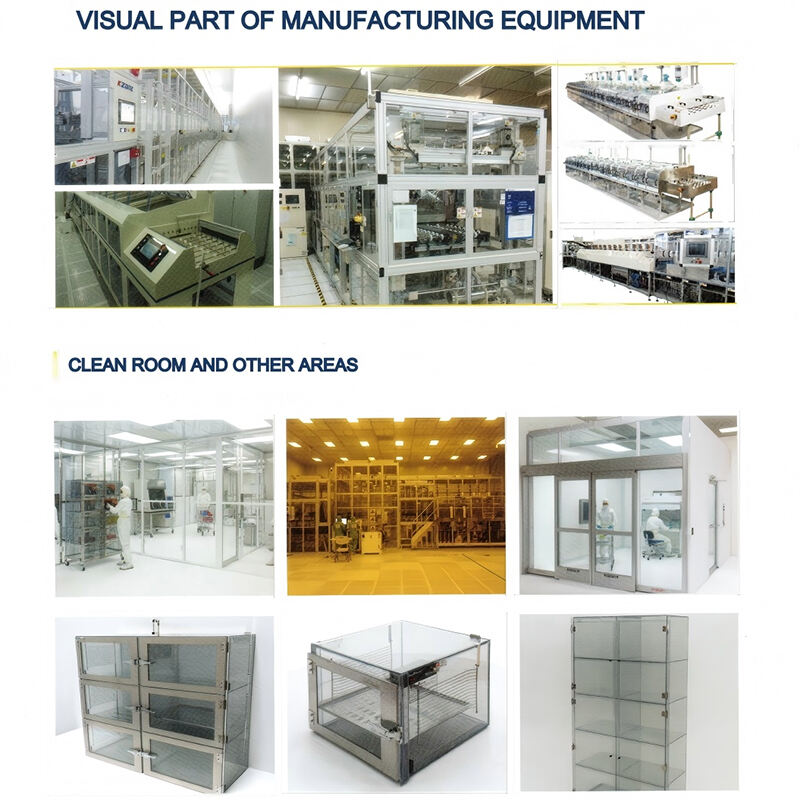

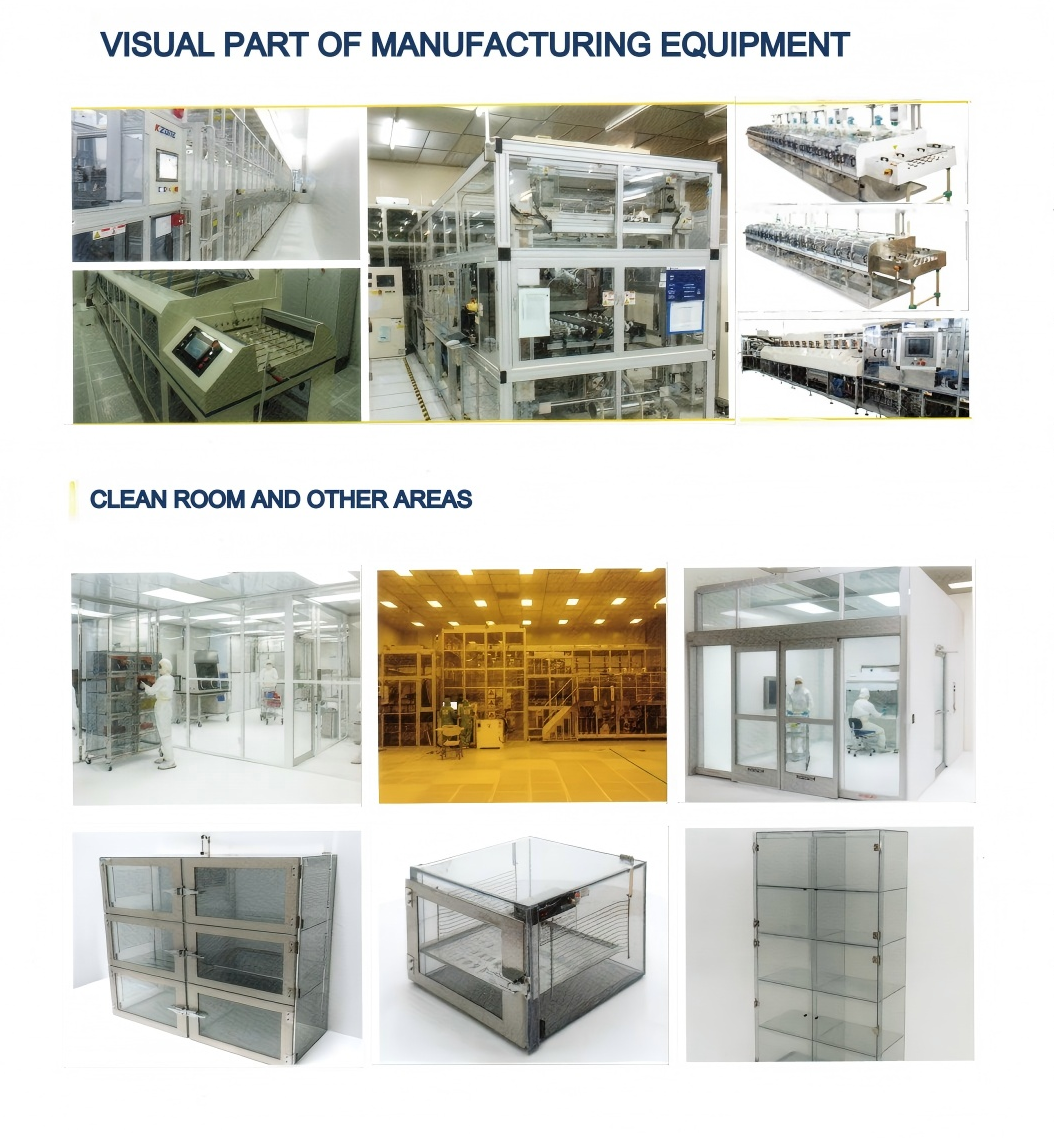

3. Semiconductor Manufacturing

The semiconductor industry relies heavily on anti-static plastics to maintain ultra-clean production environments. Static charges can disrupt photolithography processes, damage silicon wafers, or attract contaminants. Anti-static polycarbonate or PET sheets are used in cleanroom flooring, tooling fixtures, and wafer carriers. Their low particle generation and static-dissipative properties align with ISO Class 1-5 cleanroom requirements, ensuring yield optimization.

4. Aerospace Engineering

Aerospace applications demand materials that withstand extreme conditions while mitigating ESD risks. Anti-static plastic panels are used in aircraft interiors, avionics enclosures, and satellite components. For example, carbon-filled conductive plastics shield navigation systems from static interference at high altitudes. These materials also meet stringent flame-retardant and weight-saving criteria critical for the aerospace design.

5. Medical Device Safety

In healthcare, anti-static plastics ensure the safe operation of sensitive diagnostic equipment (e.g., MRI machines, surgical robots) and prevent static-induced ignition risks in oxygen-rich environments. Medical-grade ESD sheets are used for sterile packaging, surgical trays, and equipment housings, complying with FDA and ISO 13485 standards. Their biocompatibility and ease of sterilization further enhances utility.

6. Security and Defense Systems

Anti-static plastics play a role in protecting advanced security hardware, such as surveillance servers, biometric scanners, and communication devices. By preventing ESD-induced malfunctions, these materials ensure uninterrupted operation in mission-critical scenarios. Conductive additives like graphene or metalized coatings are increasingly used for EMI/RFI shielding in military-grade applications.

7. Automotive Electronics

Modern vehicles, with their reliance on electric drivetrain and ADAS (Advanced Driver-Assistance Systems), require ESD-safe materials for battery housings, sensor modules, and infotainment systems. Anti-static polypropylene or ABS sheets protect against static buildup during assembly and operation, enhancing vehicle safety and longevity.

8. Optical Industry Precision

In optics, static charges can attract dust to lenses, mirrors, or laser components, degrading performance. Anti-static acrylic or polycarbonate sheets are used for optical workstations, display covers, and lens packaging. Their optical clarity, combined with static-dissipative properties, ensures pristine surfaces for high-end cameras, microscopes, and photolithography tools.

Why Choose Anti-Static Plastics?

Surface Resistance: Ranges from 10^6 to 10^9 ohms/sq, ideal for controlled static dissipation.

Durability: Resistant to chemicals, abrasion, and temperature fluctuations.

Customization: Available in sheets, films, or molded parts with tailored conductivity.

Compliance: Meets ANSI/ESD S20.20, IEC 61340, and industry-specific certifications.

The Future of ESD Materials

As industries push toward miniaturization and io integration, the role of anti-static plastics will expand. Innovations like nanotechnology-enhanced polymers and sustainable conductive composites are poised to redefine ESD protection. For businesses, adopting these materials isn’t just a precaution—it’s a strategic advantage in an increasingly electrified world.

By leveraging anti-static plastic solutions, industries can mitigate risks, enhance productivity, and future-proof their operations. Stay charged with safety—without the static.

Keywords: Anti-static plastic sheets, ESD materials, semiconductor protection, aerospace applications, medical device packaging, static dissipation.