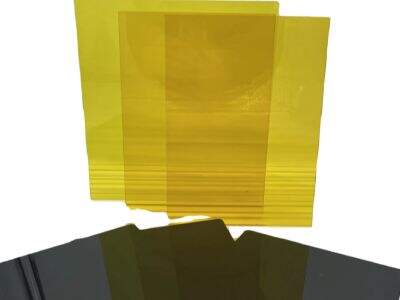

Acrylic Hard Coated Have You Heard of It? It is a unique technique to cover various surfaces with a durable as well strong layer. This is the kind of coating that gets used in a wide array of industries to help products last longer and work better. It can be found on things like furniture, cars and even electronic devices. If you would like to learn more about acrylic Hard-coating and the process of Cobot installation, read this guide.

What is Acrylic Hard Coating?

The process of acrylic hard coating includes: First thing you gotta do is get that surface ready to be coated. This means that you will have to clear it with a fervent cleaning so as to extract all the soil, dust and grease particles. Occasionally, you might have to even sand the surface smooth. There will be a step where you prime the surface, which is another fancy way of saying that this paint bonds better to whatever underneath it.

Then, it is resigned with a coat of acrylic bytes. This resin is a liquid which solidifies after drying. Once the spraying process is done, then if required by manufacturing we cure this over sprayed home surface with either heat or a unique light called dry in place UV technology. The method helps to solidify the resin and get it properly adhered on your surface. A second layer of resin is then added and cured once the first dryer. The coated surface is then inspected to ensure that it looks good, and feels flat. Occasionally, it may take a little time to polish for the perfect end result of smooth shininess. The result is a tough durable film which protects against scratching, wearing, and even chemical damage.

What to anticipate earlier than diving in

Some Things to Know When You Want to Begin Your Own Acrylic Hard Coating Project One thing you can control is making sure your surface area is clean from dust and free of oils or other impurities. This allows the Acrylic PC Sheet coating to stick and function correctly. If the exterior is not clean, then the coating may even adhere improperly and start peeling.

The next thing you must do is select the perfect type of acrylic resin to your project. There are several different kinds of pencils and each have their own purpose. Because you may want a thicker layer or faster drying time, choosing the right resin to fill your needs is crucial. Thirdly, refer to the manufacturer's guidebook. These instructions comprise of how to blend the resin, spray it on and cure. If there are any steps that change, or if you do not follow the directions properly it is guaranteed to mean an inferior finish will come out.

Acrylic hard coating that you can do with confidence

Acrylic Hard CotingThe process of acrylic hard coating seems quite complicated but worry no more. It can be your proud, new hobby if you have the tools and knowledge to perform it with confidence. Choosing the right equipment for your project is one crucial part to remember. Equipment needed: A spray gun, a compressor to help you spray the resin, a mixing cup for their materials and one scale plus thermometer mentioned above. Quality materials and tools are the only way to get a well coated, good looking job.

Secondly, it is crucial that you work in a clean and ventilated environment. Thus, you should have good airflow while working since the fumes and overspray are harmful to breathe in. Always wear proper protective gear such as goggles for your eyes protection, gloves to protect your hands from unwanted contact on chemicals or any abrasions that can occur too long when handling scrapes of metals being painted like sharp edges and hand cuts, respirator / mask so again no breathing those nasty stuffs even if it seems almost everywhere now these day with Covid-19 affecting both human health globally which make all peoples attention how cleaning effectively their surrounding areas without risking another exposure towards other Illness.

With Offices:2. Acrylic Hard Coating Dos and Donts

While making the decision regarding your acrylic anti scratch coating for polycarbonate project, it is very important for you to keep in mind some general dos and don'ts. The dos are:

Make sure you clean the surface very well before applying the goo too lure it to stick.

Pick The Resin That Suits Your Needs And Project

Use professional equipment AND good materials for a beautiful finish.

Be sure to hit all the pointers provided by your manufacturer about mixing, spraying and curing dosages.

On examination, if any cracks or issues with the coating should be looked after immediately.

On the other side of things you have: Don'ts

If you do this in high humidity or direct sunlight, the coating will dry unevenly.

Be sure to allow the curing time, as even though it cooks in two hours, you will need more than four for total drying.

If If you mix different colors of resins, this can cause issues with the finish.

And of course remember — no project is more potentially dangerous than a woodworking one, so do use appropriate safety equipment.

After all, for numerous purposes and in countless functions; acrylic hard coating proves to be an ideal protector and improver of many surfaces. The process of coating plywood is intensive, and it will take you at most only a day to finish but in return reserves the longevity offered by this method. For your acrylic hard coating projects, Andisco can provide the service for you better. Come to us with any questions or inquiries, and we will give you a quote that fits your project.