There are so many options available that it can feel very confusing when you have to choose the perfect acrylic sheets for your project. The acrylic sheets are a wonderful selection for tens of thousands over lots of matters such like DIY tasks and decorative applications at the business industry. This is due to their light weight, high-strength properties and versatile applications. They can be found in things such as signs, displays, and even some furniture.

Annealed glass is present and correct in many projects but alternatively you could go for an acrylic sheet as a bespoke solution, fitting seamlessly into your design — exactly to size. Certain types of jobs require a specific type of sheet. We wrote this guide to help you navigate through the corner of your DIY world and pick out some proper acrylic sheets for whatever project that may be.

Factors to Consider When Selecting Acrylic Sheets

ESD Properties: That essentially means electrostatic discharge. That is when this static electricity discharge happens. If your project requires ESD Acrylic Sheet, you must find the one that prevents static electricity from accumulating. This is very crucially important because the static electricity will hurt some computer of sensitive parts or that even it damages. The use of ESD acrylic sheets can enable to prevent such issues, thus keeping your project away from them.

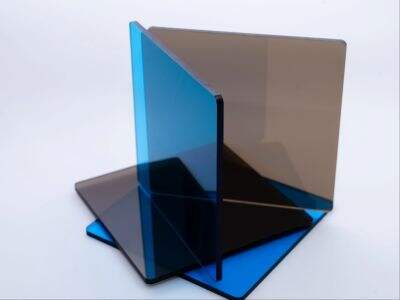

Transparency: The level of transparency used and the way it was applied. Acrylic sheets have varying levels of transparency, ranging from completely clear to non-transparent at all If you need light to filter through — when viewing the inside of a display case, for example, or showcasing an object under normal lighting conditions — then you might consider using a film. Or alternatively, you could need a sheet that cover-ups what is behind it; for reasons of privacy or visual appeal. Consider what you want your scene to look like and decide on an appropriate transparency level.

Acid fire Thickness: Acrylic sheets are available in different thickness. They may even be thin or thicker at times. Thicker sheets are often stronger, and will not bend or break as easily. But cutting and self-installation is possible only if you purchase a sheet of thinner material–or, at least it will be easier. For a project for which you need maximum strength, such as a table or shelving unit that will bear weight, opt for the thicker sheet. But a lighter sheet might work great if you just need something less dense.

While clear white acrylic board are the most common, there is a wide variety of color options available. Such colored sheets may give an interesting element to your recipe. If you are using it for your blog how does that color work with the pallet of colors in the header. Think about whether you want something that pops or goes bright and cheerful, how understated what classy. The color you select can make a real difference in the appearance of your project.

Finish: The finish of acrylic sheets may be glossy or matte, and it can also have a brushed texture. Some will be glossy; others matt and some may even have a texture. How the sheet looks and feels can be greatly changed by changing the finish. It can also contribute to its durability, meaning how well it holds up against scratches and other damage. A glossy finish can be perfect when you need your project to look more polished. For a smoother finish, matte ends are more suitable.

Tips for a Successful Project

Before You Start Cutting Your Acrylic Sheet. Measure Twice, Cut Once Measure twice and draw the line at which you want to cut. So that you not mistakes. Straight, smoother cuts can be made with a sharp edge or use cutting equipment. If you Measure: The times will be taken to measure accurately first time, and do stop from having to rip up all your work after.

Wear Safety Items: Sometimes, when we cut and rounded the edges of colored transparent acrylic then many small barbs may burst out. To protect yourself wear protective gear. You will need gloves to keep your hands safe, goggles for protecting your eyes and mask so no dust or particles get into your lung. Rule number one when working on a project is safety.

Clean the Surface: The first thing you should do, before applying glue or any kind of coatings to your acrylic sheets is cleaning. Clean With a Soft Cloth Using Soap and Water to Remove Dust. Avoid using harsh cleaners or solvents as they will scratch and damage the acrylic. Accordingly, one of the most important parts of prep work is ensuring that you have a clean surface for whatever your about to use.

Test ESD Properties: If you have a project that needs an ESD acrylic sheets, make sure to take the time and check how it works before turning this into final use. There's a tool for testing how effective they are at grounding static electricity, called an ESD meter. Also, you could put some of the material samples in different states to see how they degrade. Testing: Ensure That Your Project Is Safe and Effective

Selecting Acrylic Sheets Perfect for Your Project

Some things to consider when choosing acrylic sheets. You now have more of an idea what Considerations for Choosing Acrylic Sheets as well as some Helpful Tips, and here are a few questions you should ask yourself:

What are the acrylic sheets for anyway? Is it to avoid static cling, look nice or be sturdy? The more you know about why your project even exists the better choice you can make.

How big and of what shape should the acrylic sheet be? Is it cut-to-fit or do I need to order some special shape? Prepare in advance and save lots of time

What tools and material i need to work with acrylic sheets? Do I have room to do this safely? Run through this preparation check again before starting.

What is the budget project costs and pricing for Acrylic Sheets Good quality and price are wanted. It is essential to strike a balance between cost-effective and quality services for delivering better output within the budget.

A Simple Summary

The selection of acrylic sheets is very crucial for perfect finishing. It can impact the quality and safety of your project. When you consider the ESD properties, transparency and thickness and color and finish of a package along with these success tips, it is easier to find an option that fits your needs.

Andisco makes available numerous grades of acrylic sheets that are ESD tested and meet the most stringent requirements. We have good quality products so you can use them for your projects with minimal issues. We also provide a cut and polished service to purchase your desired sheet sizes

Whether you are an employee, a manager or simply someone who loves DIY projects in your home — visit our website and share some questions that might arise. With Andisco, we make it so that you can have a good confidence in your process and use the right acrylic sheets for your project.